Industry Trends

- Home

- Jeju Life

- Industry Trends

“JE:US, an agricultural corporation based in Jeju, derives its name from combining 'Je,' representing Jeju, and 'US,' symbolizing togetherness. We embarked on this journey to tackle the issue of an aging farming population, maximize the use of surplus agricultural products, and ultimately achieve sustainable agriculture. As a company that has grown in tandem with the region through continuous research and innovation, we will continue to adopt a broader perspective and think big to enhance the value of Jeju’s agricultural technology.”

Kim Han-sang, CEO of JE:US

|

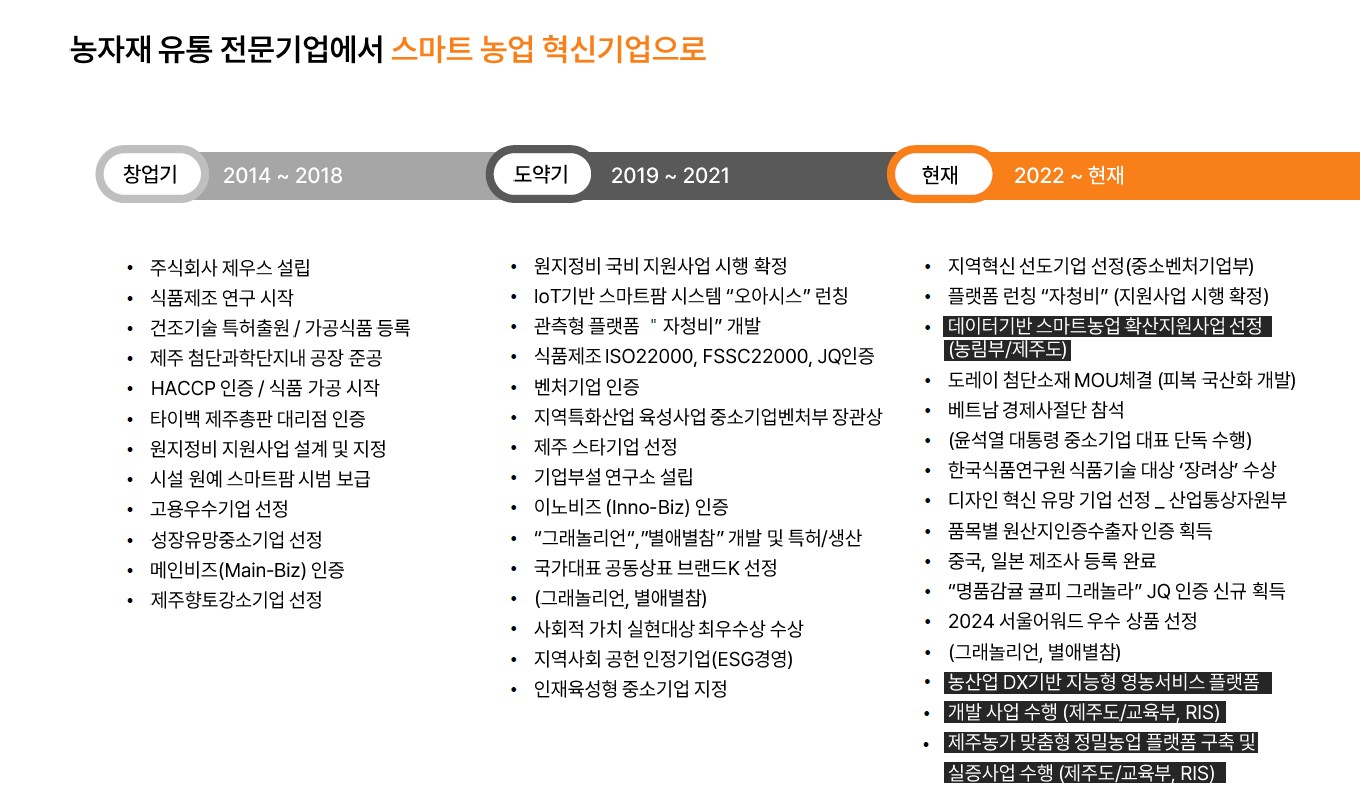

Efforts for Tomorrow's Agricultural Society |

Founded in 2014, JE:US started by distributing agricultural materials within the region. Since then, it has diversified its efforts, including Tyvek[1] cultivation consulting for high-quality tangerine production, training new farmers in agricultural technologies, and producing dried fruits to enhance the value of non-marketable produce. Recently, JE:US has focused on enhancing the quality and production efficiency of agricultural products through smart farming[2] that integrates information and communication technology (ICT). In step with the digital transformation, JE:US is leading the food tech trend, pioneering new possibilities in agriculture.

[1] A new eco-friendly nonwoven fabric made from high-density polyethylene fibers, created solely through heat and pressure without the use of any chemicals. It was developed by the global chemical company DuPont.

[2] A system that combines advanced IT technologies such as artificial intelligence (AI) and big data with traditional agriculture, livestock, and fisheries to enhance productivity.

Q. Your company began with the goal of 'contributing to increasing farmers' income.' As part of this, you introduced the orchard remodeling project to improve tangerine production.

The orchard remodeling project involves transforming low-quality tangerine orchards into high-production ones. The process takes three years. In the first year, we replant trees that have grown haphazardly in straight lines and install pest control equipment and pressure-compensating sprinklers . In the second year, we focus on training ,pruning and applying nitrogen fertilizers to help the growth of useful microorganisms. In the third year, after completing the environmental improvements, we install Tyvek on the ground and monitor growth through regular checks.

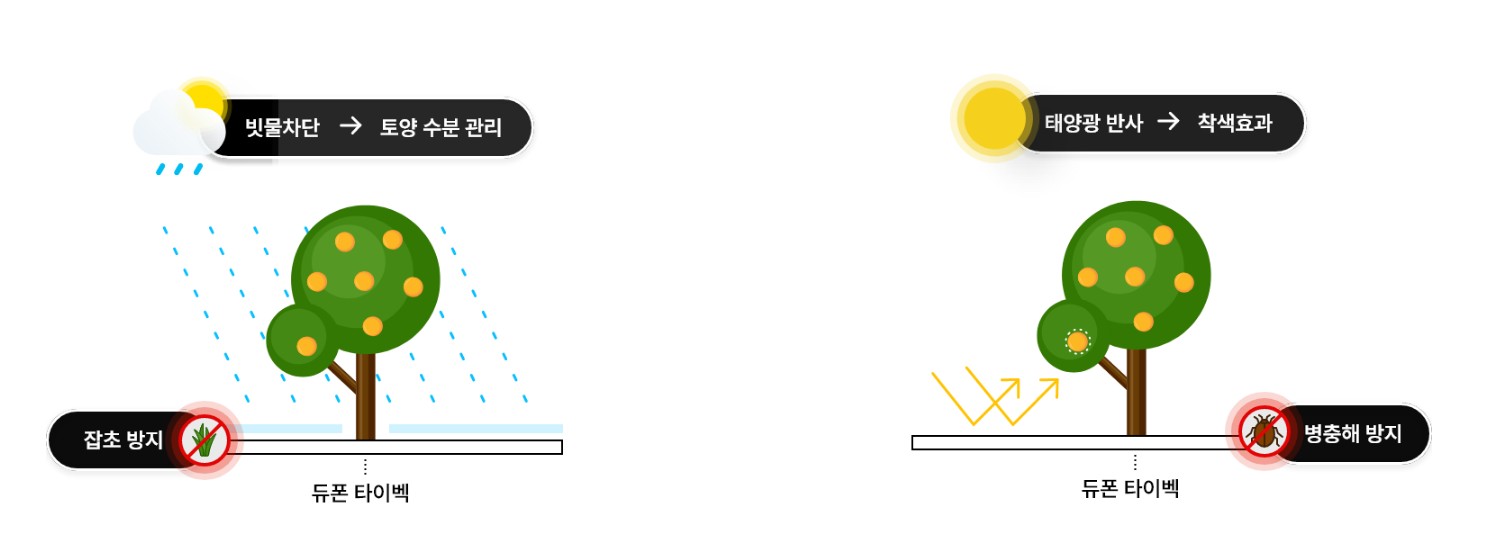

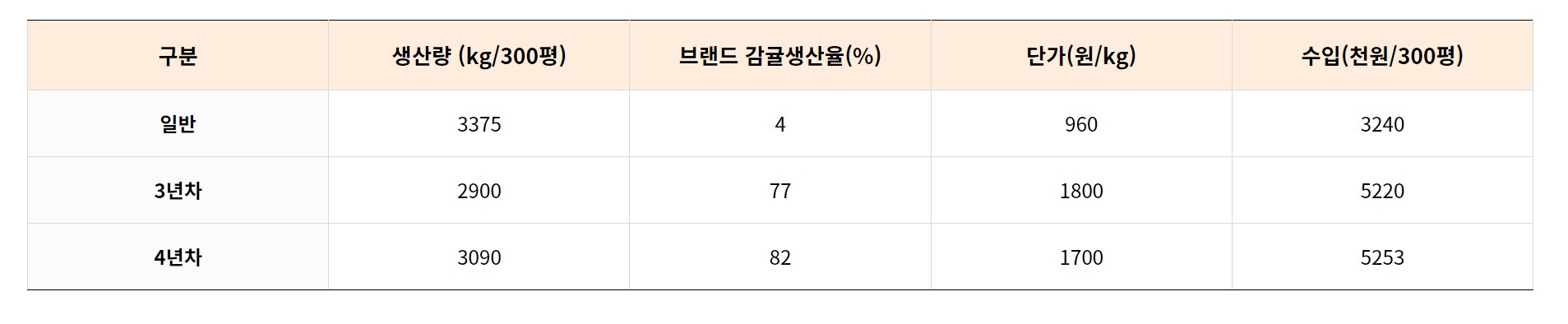

Q. What is the core technique of the orchard remodeling project, the Tyvek method?

Tyvek is a leading method for producing high-quality tangerines. JE:US is the regional distributor for Tyvek, using this technique to support the harvest of high-sugar, high-quality fruits. With its high sunlight reflectivity, comparable to black nonwoven fabric, Tyvek suppresses weed growth while evenly distributing warmth throughout the orchard. This promotes increased photosynthesis, accelerates growth, and enables an earlier harvest. Additionally, Tyvek’s small pores are effective in controlling moisture evaporation while maintaining excellent breathability, ensuring air circulation is not blocked. Its hydrophobic properties assist with soil moisture management during the rainy season.

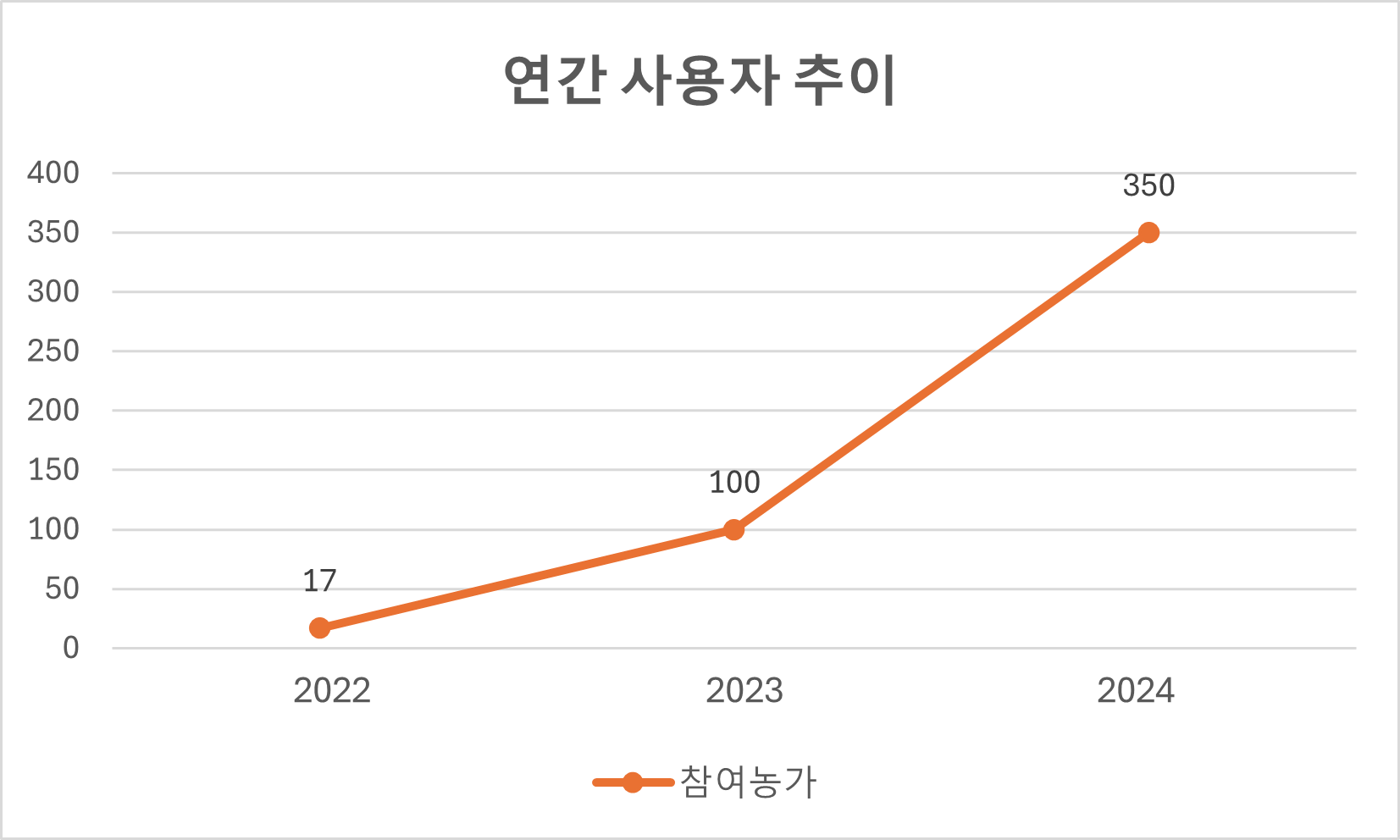

Q. What results have you seen regarding productivity increase and profitability after completing the orchard remodeling project?

After three years of remodeling, the results from the Seogwipo Agricultural Technology Center’s survey showed that the price of tangerines, which had been about KRW 900 per fruit, doubled to KRW 1,800. Moreover, the production rate of branded tangerines rose significantly from 4% to 77%.

[3] Tangerines meeting the criteria of a sugar content of 11 Brix or higher and an acidity of 1.0% or lower.

Q. Alongside this, you also offer regular agricultural consulting services.

JE:US not only provides technological solutions but also offers ongoing training for farmers to better utilize the system. This includes theoretical education on topics such as Tyvek installation and irrigation methods, as well as helpful information about government support programs that farmers might overlook. We also provide basic training for new farmers and collaborate with local institutions, like the Agricultural Technology Institute, to transfer new farming techniques.

|

Agricultural Data for High-Quality Produce |

Q. You operate an Agricultural Data Center to track crop cultivation techniques and growth conditions. How is data collected?

In 2021, JE:US launched the Jeju High-Quality Tangerine Public Data Development and Sharing Project and recruited pilot farms. These farms provided growth data for four months on the condition that they cultivate tangerines in open fields using the Tyvek method. We collected data on yield, product price, and quality, then selected the top 1% of farms, providing their data as a standard model and reference guide for others. This data is accessible through JE:US’s tangerine management app, Jacheongbi.

Q. Can you tell us about the background and development process of Jacheongbi?

Jacheongbi is a remote management app designed to reduce labor and increase productivity on farms. By analyzing growth data in real-time, it allows for remote control of devices, making farming more efficient. Recently, it was paired with JE:US’s third-generation smart farm system, AUASYS, which was developed in collaboration with Jeju Technopark (JTP). Unlike traditional smart farms, which require additional equipment, this all-in-one system simplifies operations into a single device. Here’s how it works: each tree is assigned a unique number and tagged with a chip compatible with a non-destructive sugar meter, allowing farmers to check the quality of individual trees. Data on sugar level distribution and historical changes is automatically recorded in the app, enabling farmers to identify trees with the best fruit in real-time. Additionally, the app monitors the farm’s temperature, humidity, and soil moisture content, while also predicting harvest timing and yield—ultimately contributing to increased farm income.

|

A Company Adding Value to Agriculture |

Q. You are using patented complex drying technology to produce processed products. How does this differ from existing methods?

We develop various dried foods from 150,000 tons of non-marketable produce discarded each year in Jeju. Our technology preserves the nutrition, flavor, and aroma of the original produce while providing a crispy texture. Unlike traditional hot-air drying, which takes between 12 to 72 hours, JE:US's technology achieves rapid low-temperature drying in just one hour. This method retains the original taste, color, and nutrition of the fruit while ensuring a crispy texture, similar to fried food. Some of the dried products produced include Byeol & Byeol Charm (dried fruit) and Granolien (grain-based granola). These healthy products contain no added sugar, colorants, flavorings, or preservatives and were developed after a year-long collaboration between Jeju National University’s Food Engineering Department, JTP, and JE:US’s research team.

Q. JE:US is known for consistently working with various local institutions and startups. Can you share some notable collaboration cases?

JE:US has collaborated with organizations like the Jeju National University Industry-Academic Cooperation Foundation, Route330, and JTP on R&D projects. In partnership with Jeju-based company Nanoom Energy, JE:US developed a solar-powered wireless product with support from the Jeju Free International City Development Center (JDC), which was installed on tangerine farms lacking electricity. Additionally, JE:US partnered with Jeju Milk to launch collaborative products like cheesecake, granola, and green yogurt. Furthermore, JE:US has set up a factory capable of both OEM and ODM production, fostering mutual growth with Jeju's startups and expanding the reach of primary production industries.

Q. Notably, JE:US has maintained a close relationship with JDC since the company’s early stages.

We have received multifaceted support from JDC, including assistance with research and development projects. JDC has also, directly and indirectly, supported our participation in exhibitions and fairs by facilitating buyer consultations and export meetings. Additionally, JDC has hosted lectures on ICT industry growth and the Fourth Industrial Revolution Academy, which have significantly strengthened JE:US’s capabilities as a tenant of Jeju Science Park.

Q. What are JE:US's key achievements this year, and what are your goals moving forward?

The biggest achievement this year was the development of the smart farm AUASYS and the Jacheongbi app, which directly help farmers generate income. This year proved that sustainable agriculture is achievable. Looking ahead, we aim to expand into corporate farming based on Jacheongbi starting next year. Additionally, in April, our Granolien Jeju Tangerine, produced using patented technology, was selected as an excellent product at the Seoul Awards, and in November, we received the JTP Growth Ladder Award from Jeju Technopark. Building on these achievements, JE:US's goal is to be the first local company in Jeju to list on KOSDAQ by 2028. As the Fourth Industrial Revolution reshapes all industries, we are entering an era of cross-sector collaboration. Food tech is no longer a distant concept. Agriculture is evolving, incorporating drones, sensors, and AI-powered automation systems. This transformation offers the younger generation opportunities for increased productivity, large-scale farming, and stable, high profits. In this landscape, JE:US will continue to focus on smart farm development and strive to play a foundational role in making agriculture a viable choice for future generations.

■ INFORMATION

Established in | 2014

Business line |

: Development and operation of smart agriculture

: agricultural processed food manufacturing

: distribution data platform

Homepage | jeuscorp.com

IR BOOK | JEUS 회사 소개서